Airspeed Indicator Explained: Why Is My Airspeed Indicator Leaking?

July 26, 2019

Every aircraft with a standard category airworthiness certificate must carry a working airspeed indicator, which must be checked every 24 months as part of the FAR 91.411 inspection procedures. If you notice a problem with the airspeed indicator you should have it checked immediately by an appropriately certified mechanic.

How does an Airspeed Indicator Work?

The airspeed indicator uses part of the aircraft’s pitot-static system to measure and compare the dynamic air pressure between air moving into the pitot tube and static air pressure. A thin metal diaphragm inside the instrument case flexes as the pressure changes in dynamic pressure that causes readings on the ASI.

The airspeed indicator displays the pressure differential as the indicated speed of the aircraft in miles per hour or nautical miles per hour (knots), not adjusted for temperature or general wear of indicator components.

The system relies on airtight tubing, fitting and seals between the pitot tube and static ports to the instrument to work correctly. Any part of the system could have a leak or blockage that could affect accurate readings.

Reasons your Airspeed Indicator Doesn't Work

It may be difficult to identify an airspeed indicator that's not operating according to specs. There’s a clear sign of a problem if the indicator remains at zero while you're taxing to the runway. But an airspeed indicator can give erroneous readings when there are blockages in the pitot and static system.

Here's a look at a few reasons your airspeed indicator may not be working properly. Consult with a repair shop that’s properly equipped before trying to repair any problems.

| Airspeed Indicator | |||||

| Component | Failure Mode | Level | Climb | Descent | |

| Pitot Line | Frozen/blocked | Slowly bleeds | Reads fast | Reads slow | |

| Leaks/water in line | Reads slow | Reads slow | Reads slow | ||

| Static Line | Frozen/blocked | Unaffected | Reads slow | Reads fast | |

| Partially obstructed | Unaffected | Reads slow | Reads fast | ||

Source: CFI Notebook

Pitot Tube is Clogged

Insects, ice, debris and other environmental factors can clog the tube. A clogged tube can lead to erratic readings or no reading at all. If the plane has a pitot tube drain that becomes blocked, the airspeed will change with altitude like an altimeter. It won't accurately indicate the airspeed. When the pitot tube is clogged with water in the line, but the drain remains open even after the water has drained, the airspeed indicator will read zero.

Leak in Pressurized Line

The line carrying the dynamic air to the airspeed indicator can leak, leading to inaccurate readings. Fittings and tubes can develop cracks or come loose over time.

Leak in Static Line

A leaky static line can be hard to detect in an unpressurized aircraft, and may only be found during the biannual system check. The fittings and tubes may have developed a small leak that could lead to inaccurate readings.

Leak in Instrument Case

The casing around the instrument or the fittings for the tubing could admit air, leading to inaccurate readings. A lower-than-normal indicated speed when the throttle is set for cruise RPMs may be the first sign of an air leak.

Static Port Blocked

If only the static port is blocked, the airspeed indicator will operate, but it will be inaccurate. Depending on the altitude of the aircraft when the blockage occurred, the airspeed could read higher or lower than usual during flight due to static air trapped in the instrument case.

Schedule a Maintenance Check

All mechanical airspeeds have sealing gaskets, bezel gaskets and diaphragms. Any one of these parts can cause the airspeed to leak. Age, over pressuring the diaphragm and environment will cause gaskets to deteriorate over time. It’s also important to check all lines, tubing or hoses that run through the pitot system for cracks or breaks. Make sure all connections and fittings are properly sealed.

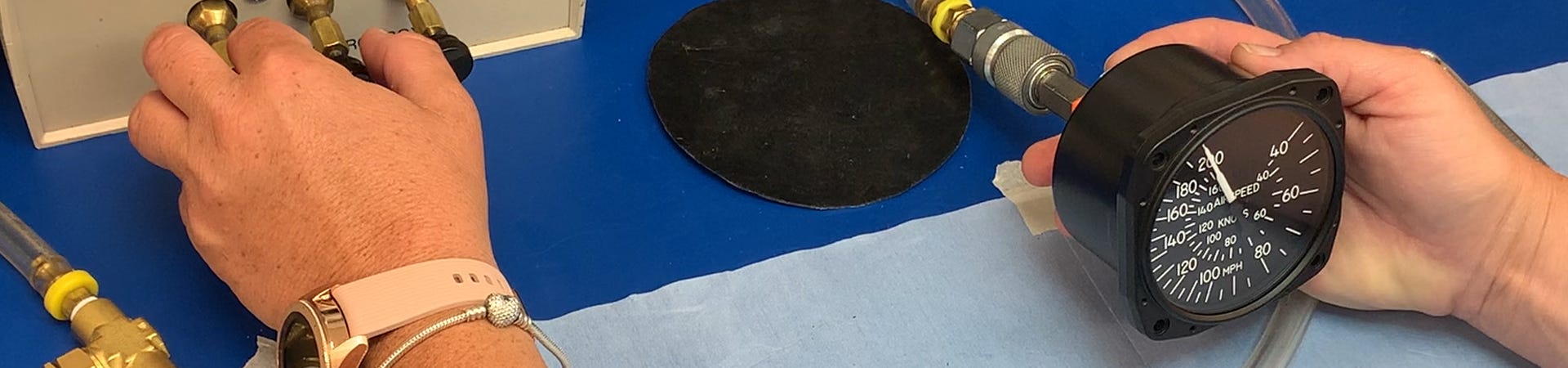

Airspeed Indicator Repair and Overhaul Services

Mid-Continent Instruments and Avionics is one of the largest, most comprehensive sources for overhaul, exchanges and repair of more than 6,000 aircraft products. If it's time to repair or even overhaul your airspeed indicator, you can access our nationwide network of dealers and repair shops to ensure your instruments meet regulations and perform to your standards.

We offer an easy-to-use overhaul and exchange program and our enhanced repair standards always meet manufacturer’s specifications. To ensure that overhauled instruments perform properly under all operating conditions, ask your local avionics dealer about our products and overhaul services. Locate an avionics dealer near you.